In the world of lean manufacturing and process optimization, few concepts are as transformative as the Gemba Walk. But what exactly does “Gemba” mean? In Japanese, “Gemba” translates to “the real place”—the location where value is created. In business, this typically refers to the shop floor or any site where actual work happens.

A Gemba Walk is a structured management practice that involves going to the front line, observing processes firsthand, and interacting with team members to gain a fresh perspective on operations. Unlike traditional audits or top-down reviews, Gemba Walks are rooted in respect, collaboration, and learning. They’re not about pointing fingers—they’re about understanding.

Leaders and managers conduct Gemba Walks not just to monitor performance, but to identify opportunities for improvement, encourage accountability, and ultimately drive continuous improvement. Whether it’s manufacturing, healthcare, logistics, or software development, this lean tool is used across industries to bridge the gap between strategy and execution.

While the Gemba Walk shares philosophies with Six Sigma, it’s more about real-time observation than data analysis. However, it does complement Six Sigma by helping identify the root causes of problems that data alone might not reveal.

The Purpose Behind Conducting Gemba Walks

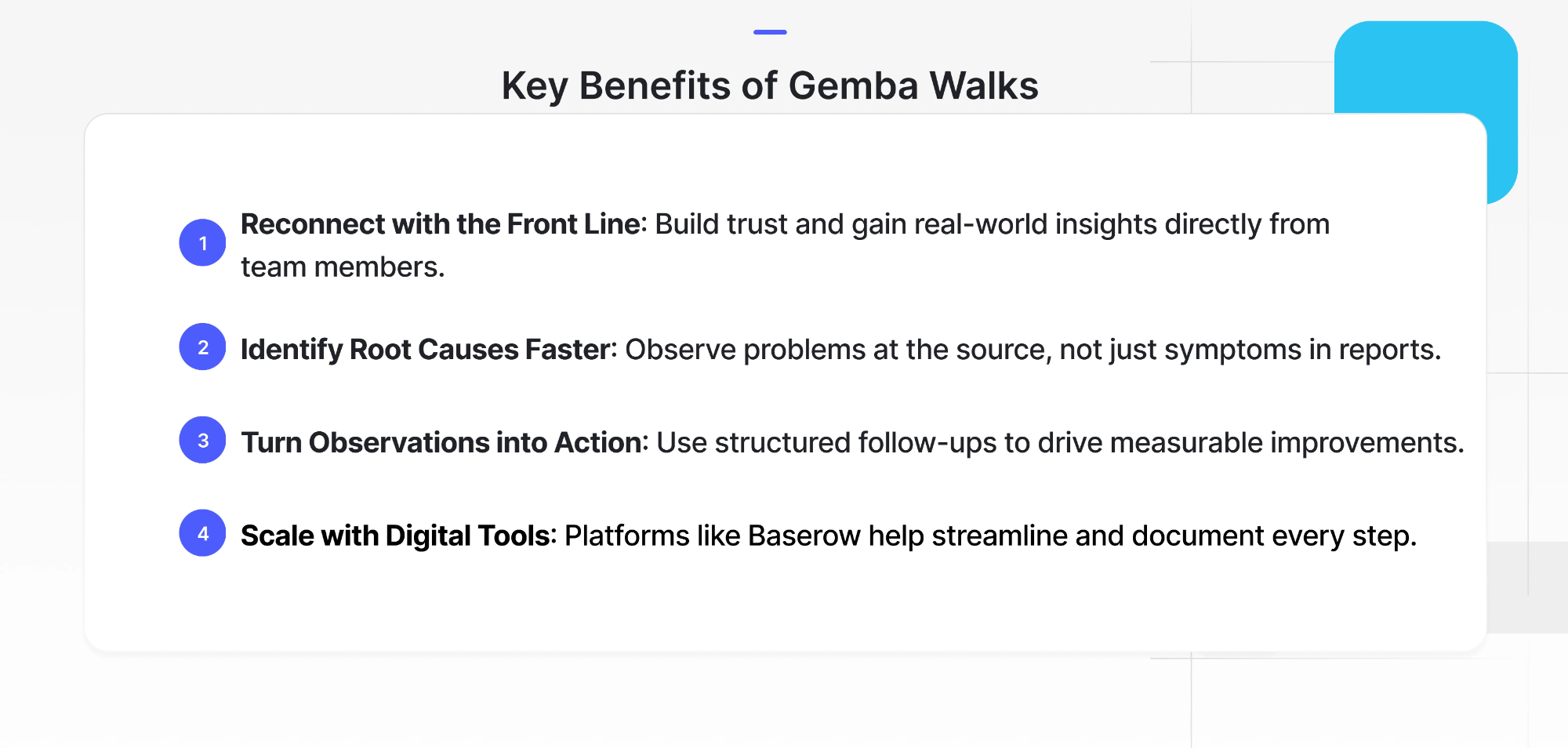

One of the core objectives of a Gemba Walk is to engage with employees—not from a meeting room or performance dashboard, but directly at their workstations. This human-centric approach fosters trust, openness, and genuine insight into daily tasks.

When leaders take the time to observe day to day operations, they better understand the flow of work from start to finish. This includes discovering bottlenecks, equipment issues, or communication gaps that often go unnoticed in traditional reporting structures. It’s an essential way to gather information that is contextual and unfiltered.

Gemba Walks also serve as a bridge between strategic initiatives and execution. Leaders can validate whether the company’s goals align with how work is actually performed. Importantly, they empower employees by inviting their input—reinforcing that those closest to the work are often the best sources of ideas for process improvement.

Another key benefit is the ability to identify inefficiencies in real time. Whether it’s unnecessary motion, long wait times, or rework, seeing the workflow directly allows managers to uncover and resolve issues that might otherwise linger.

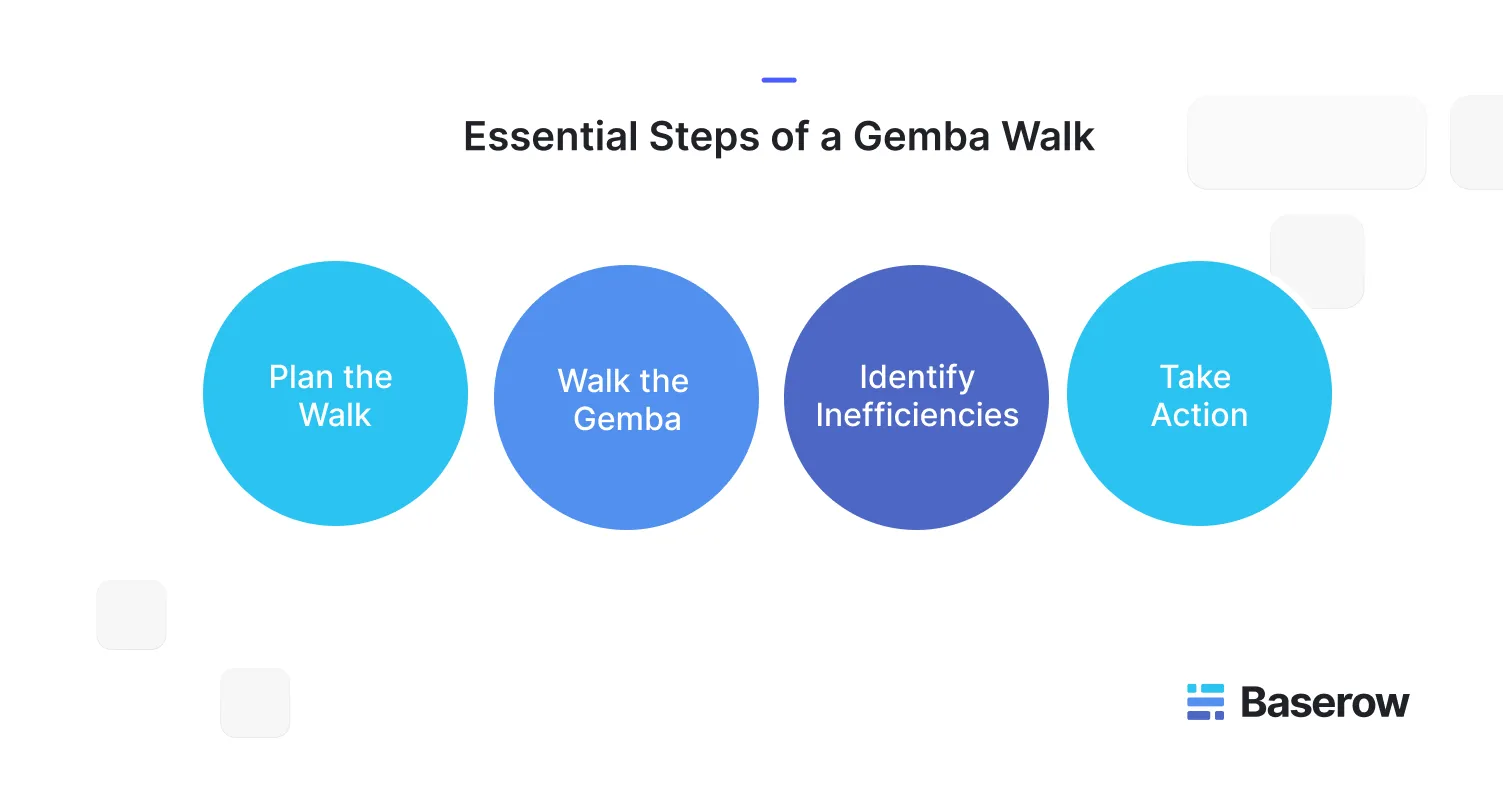

The Four Essential Steps of a Gemba Walk

While the idea of a Gemba Walk is simple, making it effective requires structure. Below are the four fundamental steps to ensure a meaningful and productive walk:

1. Plan the Walk

Before heading to the front line, it’s important to have a clear objective. Are you focusing on safety, quality, equipment usage, or communication flow? Start by preparing a Gemba Walk checklist that outlines what to observe and what questions to ask. This sets the tone and keeps the visit purposeful.

Tools like Baserow can help teams collaboratively create and update checklists tailored to different workflows. By maintaining a consistent framework, managers ensure that every walk yields actionable insights.

2. Walk the Gemba

This is the observation phase. Visit the work area, observe processes from start to finish, and most importantly, engage with team members. Ask open-ended questions: “What challenges are you facing today?” or “Is there anything that could help you work more efficiently?”

Avoid interruptions or micromanagement. The goal is to see how work naturally flows and to build rapport with the people who know the process best.

3. Ask Why & Identify Inefficiencies

As you observe, dig deeper. Why is a certain step taking longer? Why does this machine have more downtime than others? Using the “5 Whys” technique can help get to the root causes of problems rather than just treating symptoms.

Again, this isn’t about blaming individuals—it’s about identifying inefficiencies in the system and understanding their impact. Documenting these findings using a shared digital platform ensures nothing gets lost.

4. Take Action

The final step is to synthesize what you’ve seen and follow up. Whether it’s initiating a quick fix, suggesting a deeper investigation, or revising a process, the walk only adds value if it leads to improvement. Teams should also review findings collectively and update their procedures accordingly.

Conducting Gemba Walks consistently—rather than as one-off events—is what creates long-term value. Regular Gemba Walks encourage accountability, nurture a culture of transparency, and keep improvements ongoing.

Best Practices for Effective Gemba Walks

While the concept of Gemba Walks is straightforward, executing them well requires consistency, empathy, and the right mindset. Here are some of the best practices that can make your Gemba Walks truly impactful:

- Make Gemba Walks a Regular Practice

The key to long-term value lies in regular Gemba Walks, not occasional visits. When walks are scheduled and consistent, they become part of the operational rhythm. Employees grow accustomed to engaging openly, and leadership stays more attuned to the real-world challenges on the ground.

- Focus on Observation, Not Judgment

A Gemba Walk isn’t an audit. It’s a chance to see work as it truly happens. Managers should resist the urge to offer instant solutions or point out flaws in the moment. Instead, they should listen, ask questions, and document what they see. This approach helps build a safe environment where team members feel comfortable sharing problems—and potential solutions.

- Look for Opportunities, Not Mistakes

The best leaders use walks to identify opportunities for improvement, not to assign blame. When workers know the goal is learning—not punishment—they’re more likely to provide honest feedback and participate in improvements.

Effective leaders recognize that those closest to the process are often best positioned to suggest innovations. By actively listening and validating employee input, Gemba Walks become a source of organic, frontline-driven change.

- Document and Share Findings

Too many insights from Gemba Walks go unacted on because they’re scattered in notebooks, emails, or verbal reports. A digital tool like Baserow makes it easy to document observations, tag priorities, and assign follow-up actions.

You can build custom databases or use ready-made templates to track trends over time—ensuring that each walk builds on the last. This centralization is key to moving from observation to action.

Digitizing Gemba Walks with Baserow

As organizations scale, managing Gemba Walks using paper notes, spreadsheets, or disconnected tools can become a bottleneck. That’s where digital transformation steps in.

With Baserow’s Gemba Walk solution, teams can digitize their entire Gemba process—from checklist creation to action tracking. You can tailor workflows to your unique shop floor needs while maintaining the agility of a no-code platform.

For example, using Baserow, operations managers can:

- Build and reuse Gemba Walk checklists for different departments

- Document observations with rich-text fields, tags, and attachments

- Assign follow-ups to responsible team members

- Track resolution progress and analyze trends over time

This shift from manual to digital empowers teams to act faster, collaborate better, and ensure that every Gemba Walk drives measurable process improvement.

It also removes friction from knowledge sharing. Instead of siloed insights, all relevant stakeholders—from team leads to executives—have access to a shared, real-time view of continuous improvement initiatives.

In short, digitizing your Gemba Walks doesn’t just make them easier to manage—it makes them more effective.

Final Thoughts on Gemba Walks and Continuous Improvement

A Gemba Walk is more than just a management activity—it’s a mindset. It encourages leaders to step out of the boardroom and into the real world of operations, where challenges and opportunities coexist.

Whether you’re trying to improve efficiency, identify root causes of problems, or simply reconnect with your front line team, the Gemba Walk is a proven way to make it happen. When supported by a tool like Baserow, your walks can evolve from observations to structured, scalable action plans.

Ready to Start Your Digital Gemba Journey?

If you’re looking to enhance visibility, accountability, and agility in your improvement initiatives, Baserow offers a powerful platform to help. From building tailored Gemba workflows to managing continuous feedback loops, Baserow empowers your team every step of the way.

👉 Get started today and explore how Baserow can support your lean transformation.

Or, learn more with our product overview.

Baserow 2.0 introduces the automations builder, upgraded AI fields, the Kuma AI assistant, enhanced workflow logic with formulas and variables, improved workspace search, and stronger security with 2FA.

Discover how Airtable and Baserow compare in features, flexibility, speed, and scalability. Compare pricing plans and hidden costs to make an informed decision!

Explore the best open-source software alternatives to proprietary products. Discover OSS tools, licenses, and use cases with our updated directory.