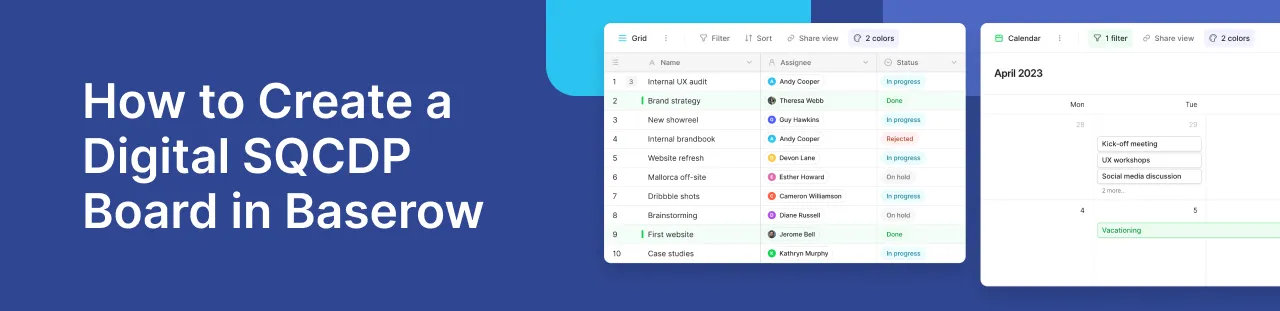

If you’re already familiar with the value of SQCDP boards, you’re likely ready to make the shift from paper-based tracking or static spreadsheets to something more dynamic. In this guide, we’ll walk you through how to create a digital SQCDP board using Baserow—a no-code tool designed to streamline performance management in manufacturing and operations.

Whether you’re tracking safety incidents, delivery delays, or quality metrics, Baserow gives you full control over how your data is structured, viewed, and used—making it easier to improve visibility and performance across your team.

Why a Digital SQCDP Board Matters for Manufacturing

The SQCDP framework—Safety, Quality, Cost, Delivery, and People—is a proven method in shop floor and lean management. But static boards and spreadsheets often fall short of today’s demands for agility, clarity, and collaboration.

Digital boards solve this by enabling:

- Real time data updates from team members

- Centralized tracking of key operational data

- Transparent visibility across teams and shifts

- Standardized reporting and quality control practices

By upgrading to a digital format, teams can stay more aligned, identify trends faster, and act on performance insights with confidence—without waiting for end-of-day updates or manual input.

New to SQCDP? Learn what an SQCDP board is and why it matters for your operations and team alignment.

Preparing to Create a Digital SQCDP Board

Before you dive into Baserow, it’s important to lay the groundwork. Here are a few things to consider when structuring your board:

- Define Your Focus Areas: Safety, Quality, Cost, Delivery, and People should each be represented with clear objectives.

- Determine Your KPIs: Choose the most relevant key metrics per pillar—such as number of safety incidents, cost per unit, OEE, or absenteeism rate.

- Assign Team Roles: Clarify who’s responsible for updating each section to encourage employee engagement.

- Set Your Meeting Rhythm: Will you update the board during daily huddles, per shift, or at weekly stand-ups?

- Align with Improvement Goals: Ensure the metrics tie back to your continuous improvement targets and broader business KPIs.

This prework ensures your board becomes a functional visual management tool, not just another dashboard.

How Baserow Helps You Build and Scale SQCDP Boards

.jpg)

Now that you’re ready to digitize your SQCDP system, Baserow gives you the structure, flexibility, and collaboration features you need. As a no-code platform, Baserow allows operations teams to build fully custom workflows without relying on developers or pre-built limitations.

Here’s how Baserow supports your SQCDP goals:

- Track performance pillars with ease: Create structured tables for each SQCDP category—Safety, Quality, Cost, Delivery, and People.

- Enable real-time collaboration: Let team members update issues and progress directly from their stations.

- Integrate data and visuals: Build dashboards that align with shift reviews and tier meetings.

- Adapt your process: Add, rename, or restructure categories as your process evolves, without disrupting operations.

This flexibility makes Baserow ideal for growing teams focused on quality control, improvement, and team alignment.

Want to explore the platform? Start here

Monitoring and Improving with Your Digital SQCDP Board

Once your board is in place, the real value comes from using it consistently to monitor and improve operations. Baserow gives teams the tools to track patterns, catch anomalies, and respond with clarity.

- Track and Visualize Performance

Use Baserow’s filtered views to compare performance across shifts, teams, or timeframes. For example, if your quality metrics show a spike in errors on the night shift, your team can dig into root causes and make targeted process adjustments.

- Improve the Working Environment

Frequent review of data—such as rising safety incidents or missed delivery targets—gives your team insight into risks before they escalate. This fosters a more proactive, safer working environment.

- Foster Accountability and Engagement

By assigning clear owners to each metric or task, team members feel more involved in the process. This boosts employee engagement and helps reinforce lean principles.

- Align with Business-Wide Goals

Digital boards don’t just serve the line—they inform the bigger picture. Data captured through Baserow becomes actionable input for plant managers and executives looking to improve the overall business across departments.

And because everything is customizable, you can evolve your SQCDP board over time—adding columns, formulas, and integrations as your process matures.

Why Baserow Is the Right Fit for SQCDP Boards

.jpg.png)

Not every tool is built for operational performance. Baserow stands out because it lets your team digitize and scale without friction. From tracking a single quality defect to managing multi-site performance data, it helps you stay responsive, consistent, and in control.

And unlike rigid enterprise software, Baserow is flexible—built to grow with your team and adapt to your real-world needs. Explore what a full SQCDP solution looks like here

Still exploring your options? Compare the best tools to create a digital SQCDP board and see how they stack up.

Get Started with Baserow Today

A digital SQCDP board isn’t just about modernization—it’s about better decision-making, higher accountability, and measurable impact.

👉 Sign up with Baserow today and empower your team with the visibility and tools they need to improve daily.

Baserow 2.1 is a maintenance-focused release that improves performance, security, and reliability. It introduces Expert formula mode, Nuxt 3 and Django upgrades, bug fixes, PostgreSQL 14+ support for self-hosters, and a new Ukrainian translation.

Discover how Airtable and Baserow compare in features, flexibility, speed, and scalability. Compare pricing plans and hidden costs to make an informed decision!

Explore the best open-source software alternatives to proprietary products. Discover OSS tools, licenses, and use cases with our updated directory.