Digital transformation has touched nearly every part of manufacturing and operations—and daily performance tracking is no exception. For teams aiming to enhance shop floor visibility, data accuracy, and continuous improvement, digital SQCDP board tools are proving essential.

Whether you’re transitioning from a physical board or looking to upgrade your existing setup, this guide will help you understand what to look for in digital SQCDP solutions and how to choose the right platform for your needs.

Why Digital SQCDP Boards Matter Today

The SQCDP framework—short for Safety, Quality, Cost, Delivery, and People—is at the heart of lean operations. Traditionally managed through whiteboards and markers, SQCDP boards enable teams to visualize operational performance at a glance.

But in modern manufacturing environments where data moves fast and decisions must be made faster, paper-based systems no longer suffice. Here’s why digital SQCDP boards are a game changer:

- Real time data helps teams respond quickly to issues as they arise

- Visual dashboards improve employee engagement by making KPIs more accessible

- Digital boards integrate easily with other systems, improving consistency and reducing manual errors

- They support shop floor management practices by enabling structured, daily review meetings—whether in person or remote

With the right tool, digital SQCDP boards empower teams to monitor key metrics, streamline reporting, and foster alignment across departments.

Check out a detailed guide on what is SQCDP Board and when does a team needs it.

Key Features to Look for in Digital SQCDP Board Tools

Choosing the right tool isn’t just about digitalizing your board—it’s about amplifying its effectiveness. Here are some critical features to prioritize:

1. Visual Management Tools

Your SQCDP board should serve as a visual control system, helping teams spot performance trends and identify areas for improvement. Look for platforms that support traffic light indicators (green/yellow/red), charts, and graphs.

2. Data-Driven Metrics

Whether tracking quality metrics, absenteeism, downtime, or safety alerts, your tool should support customizable data structures that adapt to your operations.

3. Real-Time Collaboration

For daily huddles and shift meetings, it’s essential that updates reflect instantly across teams. Real-time collaboration ensures consistency and prevents miscommunication.

4. Support for Corrective Actions

An effective SQCDP tool should let you document corrective actions directly from issues logged. This improves accountability and supports your continuous improvement initiatives.

5. Easy Setup and Scalability

From small teams to multi-site operations, your tool should grow with your business—ideally without needing developers or complex integrations.

Best Digital SQCDP Board Tools Compared

The market offers a range of tools that can be adapted for digital SQCDP boards. Here’s a breakdown of popular platforms and how they stack up:

1. Baserow

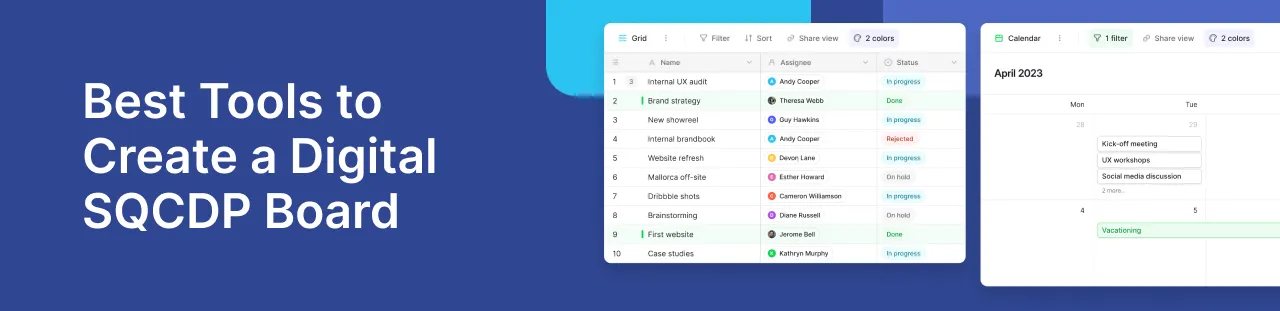

Baserow is a no-code database platform ideal for building digital SQCDP boards from the ground up. With an intuitive spreadsheet-style interface, customizable views, and powerful collaboration features, Baserow offers:

- Structured tracking for all five SQCDP pillars

- Visual indicators and dashboards for quick insights

- Built-in task management for corrective actions

- Real-time updates accessible across teams

What sets Baserow apart is its flexibility—it adapts to your existing workflows without requiring a developer. It’s especially useful for teams focused on improvement efforts and lean management.

Learn more about how Baserow supports SQCDP systems here.

.jpg)

2. Google Sheets or Excel

These tools are familiar, free, and highly customizable. However, they often require manual data entry and lack native features for workflow automation or real-time collaboration.

Pros: Easy to start, no extra cost

Cons: Limited scalability, high error risk, no built-in visual dashboards

3. Power BI

Power BI is a powerful analytics tool that can visualize complex datasets across manufacturing lines. However, it’s more suited for analysis than day-to-day operations and requires technical setup.

Pros: Advanced visualization, strong for aggregated data

Cons: Not built for frontline use or live updates

4. Notion or Trello

Lightweight platforms like Notion and Trello offer flexibility for teams looking to document their SQCDP processes. They can be adapted for light tracking but lack depth in analytics and data structuring.

Pros: Good for documentation, checklists, team notes

Cons: Not purpose-built for manufacturing KPIs or SQCDP

How Digital Tools Accelerate Continuous Improvement

SQCDP boards are not just about tracking performance—they’re a vehicle for ongoing growth and problem-solving. The right digital SQCDP tool allows you to:

- Spot inefficiencies early and identify areas for improvement

- Record and follow up on corrective actions across teams

- Improve oversight on factors like raw materials availability, safety compliance, and team workflow

- Elevate quality control by connecting metrics to insights in a single interface

These capabilities are critical for sustaining continuous improvement initiatives and scaling impact beyond a single production line. With digital platforms, frontline operators and leaders can both engage meaningfully—fostering transparency and accountability throughout the organization.

Mistakes to Avoid When Choosing a Digital SQCDP Tool

Many teams make the leap to digital systems but overlook foundational needs. A few common pitfalls include:

- Selecting overly complex or technical software that’s difficult to update in real time

- Relying on tools without structured databases—leading to inconsistent metric tracking

- Failing to connect SQCDP with actual operational reviews, such as Gemba walk mistakes, where leaders walk the floor with static or outdated dashboards

To succeed, your tool should fit your team’s workflow, support data automation, and promote active participation from everyone involved.

Why Baserow is a Smart Choice for Digital SQCDP Boards

If you’re looking for a solution that’s powerful yet approachable, Baserow offers a unique advantage. It combines the simplicity of a spreadsheet with the structure of a database—making it perfect for tracking key metrics like defect rates, safety alerts, and delivery delays.

Baserow’s no-code setup encourages skill development and ownership at every level of the organization, while its dashboards make it easier to review performance across shifts or sites. Whether your goal is to improve your working environment, streamline reporting, or deliver quality products more efficiently, Baserow enables you to do it all—without the overhead of traditional ERP systems.

Choosing the Best Fit for Your Operations Team

Digitizing your SQCDP board is more than a tech upgrade—it’s a strategic move to empower your teams and modernize your operations. By choosing the right platform, you can connect data, people, and processes in ways that drive real impact.

If you’re ready to transform how you manage safety, quality, cost, delivery, and people, we invite you to explore how Baserow can help.

👉 Start for free with Baserow today and bring your SQCDP system to life—visually, collaboratively, and effectively.

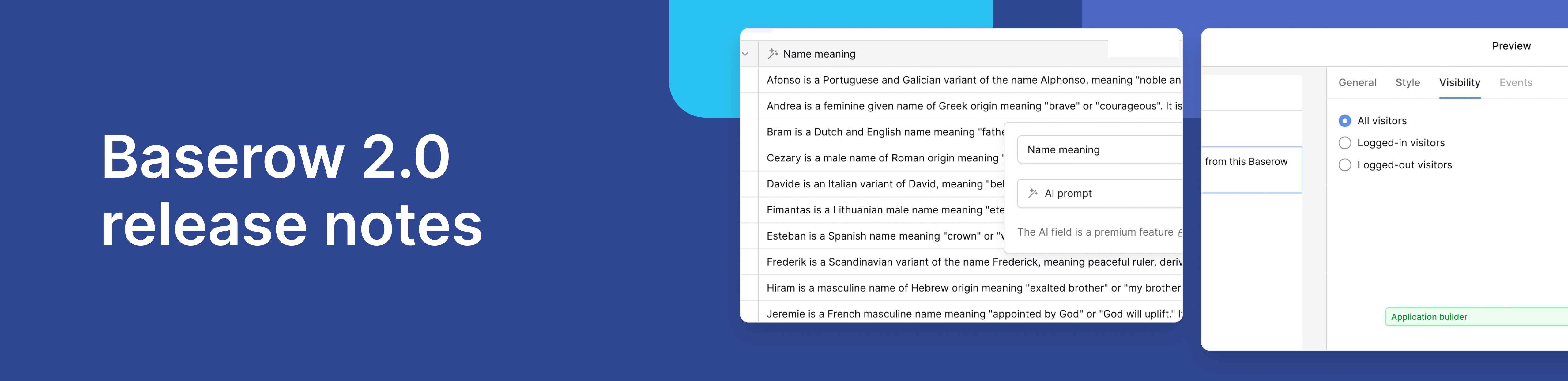

Baserow 2.0 introduces the automations builder, upgraded AI fields, the Kuma AI assistant, enhanced workflow logic with formulas and variables, improved workspace search, and stronger security with 2FA.

Discover how Airtable and Baserow compare in features, flexibility, speed, and scalability. Compare pricing plans and hidden costs to make an informed decision!

Explore the best open-source software alternatives to proprietary products. Discover OSS tools, licenses, and use cases with our updated directory.