Why Gemba Walks Fail – A Real-World Problem

The term Gemba, a Japanese word meaning “the real place,” comes from the world of Lean thinking—particularly the Toyota Production System pioneered by Taiichi Ohno. It refers to the place where work actually happens, most often the shop floor. Gemba Walks are a foundational lean practice that encourages leaders to leave the office and observe operations firsthand—at the source.

The idea sounds simple: walk the floor, observe processes, engage with frontline workers, and uncover hidden inefficiencies. However, when not executed thoughtfully, Gemba Walks can do more harm than good. Poorly conducted walks can break trust, waste time, or result in inaction—diluting the very principle of continuous improvement they’re meant to support.

Over time, many teams have fallen into common traps that turn this valuable tool into just another management ritual. Let’s examine the most frequent Gemba walk mistakes and how to correct them—before they stall your improvement efforts.

Top 8 Gemba Walk Mistakes (and How to Fix Them)

.jpg)

1. Lack of Clear Purpose

A Gemba Walk without direction is like wandering through a forest without a map. Leaders who walk the floor without a clear intent often fail to notice key issues or waste employees’ time asking random questions.

Instead, define a focus before each walk. Are you evaluating safety protocols, investigating a drop in quality, or trying to understand delays in production? Pre-walk planning, including structured checklists and themes, provides clarity.

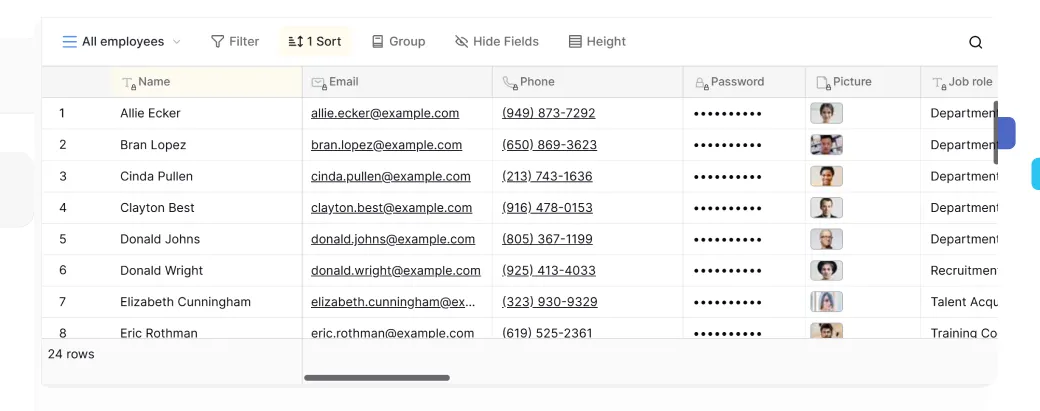

Tools like Baserow allow teams to build and reuse Gemba Walk checklists aligned to business goals, ensuring every walk starts with intent.

2. Not Engaging With Team Members

One of the biggest mistakes is treating Gemba Walks as passive observation exercises. Managers stroll past workstations, take mental notes, but don’t speak to the people doing the work. This leads to missed context—and missed opportunities.

Team members are the closest to the processes and often the best source of insights. A good Gemba Walk involves respectful dialogue: ask open-ended questions, listen actively, and avoid blame.

Want to build trust? Start by asking, “What challenges are you facing today?” It signals that you’re there to support, not judge.

3. Focusing on People, Not Processes

Too often, leaders focus on who is making mistakes instead of focusing on processes that lead to those outcomes. This undermines the spirit of Lean, where the goal is to improve the system, not punish individuals.

Blaming workers erodes trust and silences feedback. Instead, examine process flow, standard work, and equipment. Are the tools sufficient? Are instructions clear? Are delays caused by upstream issues?

The root cause is rarely a person—more often, it’s the process. By shifting focus, Gemba Walks become a tool for problem solving, not finger-pointing.

4. Irregular or Infrequent Walks

One-off or inconsistent Gemba Walks feel performative. If leaders only appear during crises or quarterly reviews, employees may see it as a performance check rather than a learning opportunity.

Should Gemba walks be done once a week? While frequency can vary, a weekly cadence is ideal to foster continuity and trust. It signals that leadership is invested in real-time problem solving—not just results.

Baserow makes scheduling and logging Gemba Walks easy, helping teams stay accountable to a regular improvement rhythm.

5. No Follow-Up or Action Taken

Perhaps the most demoralizing Gemba Walk mistake is failing to follow through. If feedback is gathered but never addressed, team members lose trust in the process—and in leadership.

Leaders must translate observations into action. Assign tasks, track progress, and communicate results. This is where digital tools shine. Baserow enables teams to assign follow-ups, set deadlines, and build dashboards that show progress transparently.

The walk doesn’t end when you leave the floor—it ends when improvement has been implemented.

6. Skipping the Front Lines

Another common mistake is conducting Gemba Walks only in areas where management is present—bypassing the front lines where actual value is created. These are the stations where production happens, where patient care is delivered, or where customer support takes place.

When leaders avoid visiting the shop floor and engage only with mid-level supervisors, they miss real-world insights. The true purpose of a Gemba Walk is to see the flow of value creation as it happens—not filtered through layers of interpretation.

To get the full picture, leaders must step into the daily context of the frontline workforce, watch tasks being performed, and ask, “What’s slowing you down today?” This is how real breakthroughs happen.

7. Rushing the Process

Speed-walking through departments just to “check the box” is another ineffective Gemba Walk practice. These rushed visits lack depth, leading to superficial insights and disengaged employees.

Effective Gemba Walks take time. Observing a full cycle from start to finish—whether it’s assembling a product, processing an order, or resolving a customer issue—yields deeper understanding. Rushed walks also discourage meaningful conversations and increase the likelihood of missing important signals.

Even a 15-minute focused walk with a clear intent can be powerful if done thoughtfully. Slowing down allows leaders to truly connect and analyze.

8. Failing to Capture Learnings

Many Gemba Walks result in verbal insights or handwritten notes that never go beyond the walk. With no centralized documentation, issues are forgotten, trends are lost, and improvements are inconsistent.

This undermines the learning loop that makes Lean effective. If you can’t track what you’ve learned, you can’t find opportunities for systemic change.

Instead, capture insights digitally. With Baserow, teams can document observations, tag recurring issues, link images or files, and create reports across time periods. You can also connect walk data to broader improvement initiatives.

Structured documentation supports real change—not just good intentions.

How to Find Opportunities During Gemba Walks

The most successful leaders approach Gemba Walks not with the goal of finding problems, but of discovering opportunities for improvement. This mindset shift changes how team members perceive your presence: you’re there to help, not evaluate.

So, what is a good Gemba Walk? It’s one where the leader:

- Focuses on the process, not the person

- Listens more than talks

- Asks questions that lead to insights

- Leaves with ideas that can be tested or improved

Gemba Walks aren’t meant to be audits—they are meant to deepen your understanding of how work happens and how it can be improved.

New to Gemba Walks or want to revisit the fundamentals? Check out our introductory guide: What is a Gemba Walk?

How Baserow Helps You Avoid These Mistakes

Traditional methods like paper checklists or spreadsheets often lead to the very mistakes we just covered—missed follow-ups, disconnected notes, and siloed learnings.

Here’s how Baserow helps turn your Gemba Walks into scalable, collaborative improvement engines:

- Build & Share Custom Gemba Walk Checklists: Easily set themes for each walk—safety, quality, downtime, or productivity—and reuse templates tailored to your team or department.

- Document in Real Time on the Shop Floor: Capture photos, text, and context as you walk, with mobile-friendly databases that make on-the-go data entry seamless.

- Engage with Team Members Through Comment Threads: Record dialogue or issues mentioned by employees, so nothing gets lost or misunderstood later.

- Track Action Items and Assign Owners: Link follow-ups to specific people and timelines, increasing visibility and accountability across the team.

- Create Dashboards for Pattern Analysis: Identify recurring problems and improvement trends through visualized data—spot weak points, and act faster.

Visit the Gemba Walk Solution Page to see how Baserow supports real-time collaboration and transparency for modern operations teams.

Final Thoughts – Make Your Gemba Walks Count

When done well, Gemba Walks are a cornerstone of Lean culture. They help leaders understand workflows, connect with frontline staff, and drive long-term continuous improvement.

But when done poorly, they become a disconnected ritual—ineffective and even harmful to trust and morale. Avoiding the most common Gemba walk mistakes takes intention, structure, and the right tools.

If you’re serious about using Gemba Walks as a mechanism for real change, don’t rely on scattered notes or isolated spreadsheets. Baserow gives your team the power to plan, execute, and evolve Gemba Walks with clarity and accountability.

Start Improving Your Gemba Walks Today

Ready to conduct smarter, more consistent Gemba Walks?

Join the teams who are using Baserow to transform how they observe, engage, and improve operations—from the shop floor to the leadership boardroom.

👉 Sign up now to start building your Gemba workflow, or explore our product overview to see what’s possible.

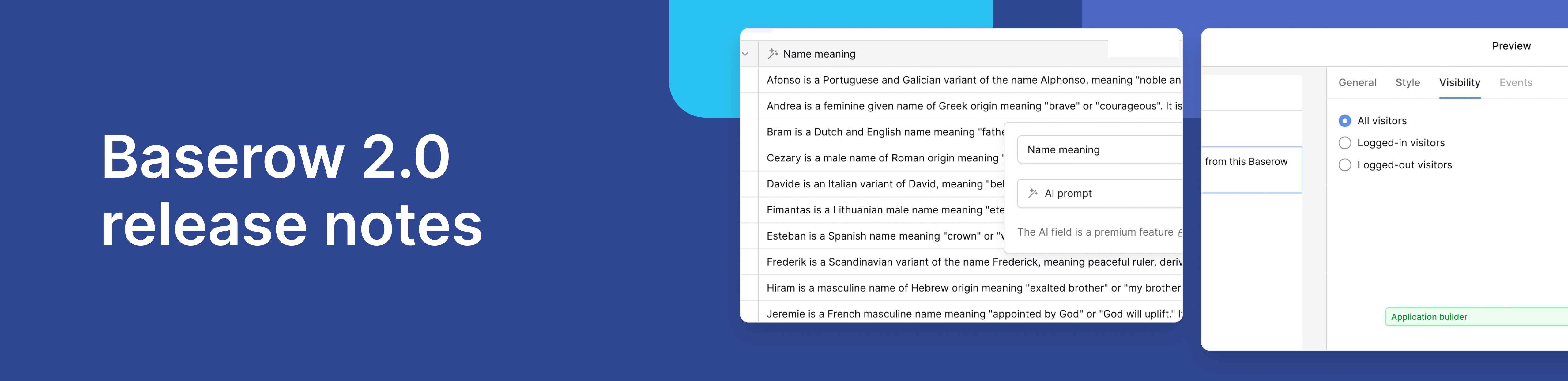

Baserow 2.0 introduces the automations builder, upgraded AI fields, the Kuma AI assistant, enhanced workflow logic with formulas and variables, improved workspace search, and stronger security with 2FA.

Discover how Airtable and Baserow compare in features, flexibility, speed, and scalability. Compare pricing plans and hidden costs to make an informed decision!

Explore the best open-source software alternatives to proprietary products. Discover OSS tools, licenses, and use cases with our updated directory.