In the dynamic world of manufacturing and operations, staying ahead requires more than just reacting to issues—it demands a proactive, visual, and collaborative system to ensure performance is continuously improving. Enter the SQCDP board, a powerful lean management tool that helps teams track progress, identify challenges, and take corrective actions across core operational areas.

What Does SQCDP Stand For?

.png)

SQCDP is an acronym that stands for Safety, Quality, Cost, Delivery, and People. It serves as a daily management framework used primarily in manufacturing environments to monitor and improve essential business metrics. Here’s a quick breakdown of what each pillar represents:

- Safety – Tracking of safety incidents and promoting a safer working environment.

- Quality – Monitoring product quality and identifying any quality issues.

- Cost – Ensuring efficient use of resources and cost-effective processes.

- Delivery – Meeting production and delivery deadlines reliably.

- People – Engaging team members and maintaining a motivated, skilled workforce.

Together, these five pillars offer a holistic view of operational performance and are widely recognized as visual management tools in lean manufacturing systems.

What is the Purpose of an SQCDP Board?

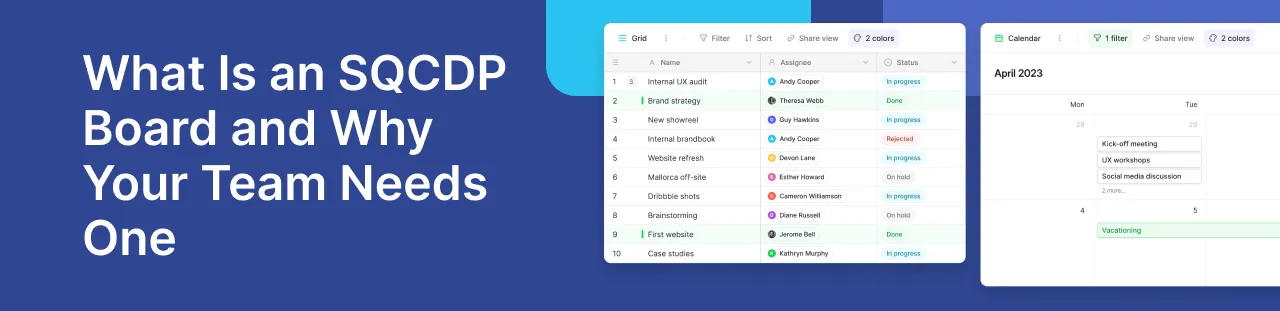

An SQCDP board brings the above framework to life—offering a visual, easy-to-understand representation of how a team or department is performing across each area. The board is typically updated daily and reviewed in short, structured meetings (often called “stand-up” or “tier” meetings). The goal is to:

- Encourage frontline employee engagement

- Promote accountability through visual tracking

- Foster real-time problem solving based on data

- Provide transparency to management and teams alike

Instead of siloed reports, the SQCDP board offers a shared space where performance issues are surfaced and resolved collaboratively.

Benefits of Using SQCDP Boards in Manufacturing

Companies that implement SQCDP boards—especially in a digital format—report significant gains in operational efficiency. Here’s how these boards help:

- Improve productivity: Teams have a daily focus on performance metrics, enabling quicker reactions and better prioritization of tasks.

- Improve quality: Visualizing quality metrics makes it easier to detect issues early and apply corrective actions.

- Enhance employee engagement: SQCDP encourages ownership by letting operators track and update their own area of responsibility.

- Drive continuous improvement: Trends and insights emerge clearly over time, leading to long-term process refinement.

- Foster safety awareness: By tracking safety incidents, teams become more aware of hazards and preventive practices.

- Support KPI alignment: Performance is tracked using predefined key performance indicators (KPIs), ensuring alignment with strategic goals.

- Optimize the working environment: Daily discussions and transparency improve communication and collaboration between team members.

The structured nature of SQCDP not only boosts performance but also creates a strong culture of continuous improvement.

How to Set Up a Digital SQCDP Board

Traditional SQCDP boards are often physical whiteboards placed in production areas. While effective, they can be time-consuming to maintain and limited in how they present and store data. That’s where digital SQCDP boards come in.

Using a digital platform allows you to:

- Update data in real time

- Automate metrics and reporting

- Easily access historical performance data

- Share insights across teams, even in remote environments

Digitize Your SQCDP Board with Baserow

Transitioning from a manual SQCDP board to a digital one opens up new levels of efficiency and visibility—and Baserow makes that transformation seamless. As a no-code platform built for flexibility, Baserow empowers teams to design SQCDP boards tailored to their unique manufacturing process and performance goals. With powerful features like customizable databases, real-time collaboration, and visual dashboards, Baserow turns your SQCDP framework into a dynamic, data-driven system.

.jpg)

Whether you’re tracking safety incidents, monitoring delivery metrics, or managing quality issues, Baserow ensures that your entire team stays aligned and informed—no matter where they are. Explore how you can build a digital SQCDP board using Baserow’s solutions here.

Real-World Examples of SQCDP Boards in Use

Let’s look at how SQCDP boards are being applied across industries to transform manufacturing operations and improve performance outcomes.

1. Improving Product Quality in Automotive Manufacturing

An automotive plant faced recurring quality issues during assembly, leading to rework and delays. By implementing an SQCDP board, they began tracking daily defects under the Quality pillar. This visibility allowed them to isolate problem areas and deploy targeted corrective actions. Over three months, defect rates dropped by 23%, highlighting the value of consistent monitoring and team involvement.

2. Reducing Downtime in a Food Production Facility

In a high-volume food production environment, unplanned downtime was affecting on-time deliveries. The SQCDP board’s Delivery column tracked downtime events, while the Cost pillar captured waste metrics. Using this real-time data, the team identified the root cause—equipment misalignment—and adjusted maintenance schedules. Delivery KPIs quickly improved, and cost overruns reduced significantly.

3. Driving Continuous Improvement in Pharma

A pharmaceutical manufacturer introduced a digital SQCDP board via Baserow to connect cross-functional teams across different shifts. Teams used it to flag safety risks and update actions collaboratively. With visual dashboards and live updates, leaders could instantly review performance across multiple lines, fostering agile problem solving and stronger process control.

Best Practices for Maintaining SQCDP Boards

To make the most of your SQCDP framework, consistency and clarity are key. Here are some best practices:

- Update the board daily: Whether physical or digital, the board should reflect the current status of operations.

- Use clear visual indicators: Red/yellow/green statuses for KPIs make trends and issues immediately visible.

- Assign ownership: Each SQCDP pillar should have a responsible team member to ensure accountability.

- Leverage real-time data: With tools like Baserow, automatic updates remove manual errors and speed up decision-making.

- Review during daily huddles: A 10–15 minute structured meeting around the board boosts employee engagement and fosters team alignment.

Digital boards, particularly those powered by no-code platforms, offer significant advantages in sustainability, collaboration, and analytics over manual systems.

Final Thoughts

The SQCDP board is more than just a visual aid—it’s a strategic framework that enables frontline teams to take charge of operational excellence. By focusing on safety, quality, cost, delivery, and people, organizations can break down silos, highlight performance gaps, and align efforts toward common goals.

When implemented well, SQCDP boards offer measurable results: they help improve productivity, boost product quality, enhance the working environment, and support a culture of continuous improvement. But for modern teams, the power of SQCDP is amplified when it goes digital.

Digital SQCDP boards enable better data integrity, real-time updates, and seamless team collaboration. They eliminate the limitations of physical boards and open the door to deeper insights and automation.

No-code platforms like Baserow make it easy to bring your SQCDP system online—without the need for complex software or coding skills. With Baserow, you can structure your board exactly the way your operations demand, visualize trends instantly, and involve all team members in tracking progress and driving results.

Whether you’re starting from scratch or replacing manual tracking methods, a digital SQCDP board is a powerful way to modernize your manufacturing process and unlock higher levels of performance.

Ready to Build Your Digital SQCDP Board?

Start today with Baserow’s no-code platform and see how easy it is to visualize performance, streamline operations, and empower your teams. Your journey to smarter operations begins now.

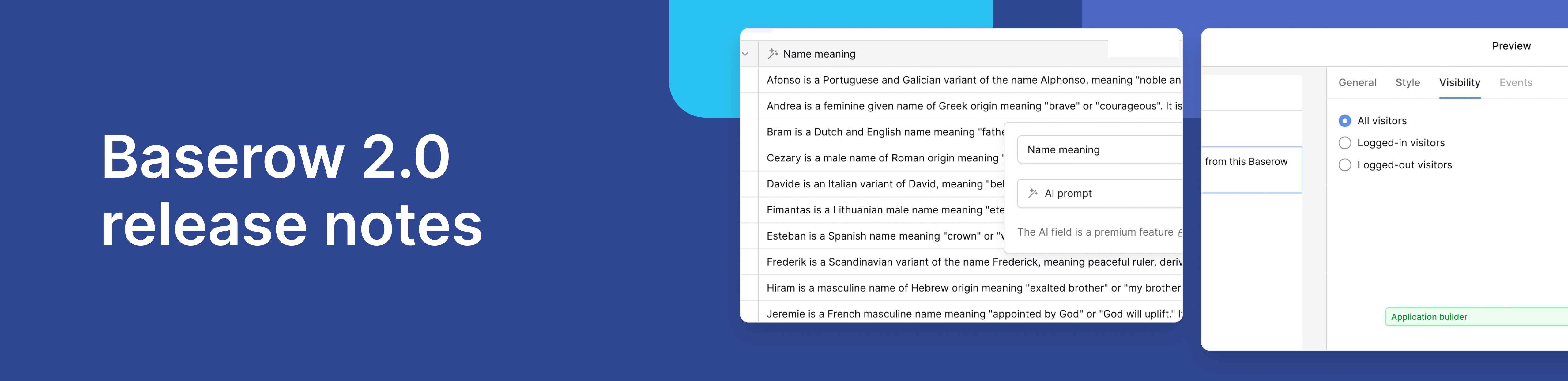

Baserow 2.0 introduces the automations builder, upgraded AI fields, the Kuma AI assistant, enhanced workflow logic with formulas and variables, improved workspace search, and stronger security with 2FA.

Discover how Airtable and Baserow compare in features, flexibility, speed, and scalability. Compare pricing plans and hidden costs to make an informed decision!

Explore the best open-source software alternatives to proprietary products. Discover OSS tools, licenses, and use cases with our updated directory.