Manufacturing teams work in environments where precision, timing, and coordination directly affect output and profitability. However, many organisations still depend on disconnected systems, spreadsheets, and email updates to manage production data, quality records, and operational plans. As manufacturing becomes more distributed and technology driven, these disconnected approaches reduce visibility and slow down decision-making.

This is where data collaboration tools for manufacturing teams become important. Unlike basic tools that focus only on messaging or document sharing, these platforms allow teams to collaborate around structured and shared data. Production planners, operations managers, quality teams, and suppliers can work in the same datasets, track updates as they occur, and respond faster to issues on the shop floor.

Modern manufacturing also depends more on remote work and coordination across locations. Engineers may review specifications from different sites, while managers monitor performance across multiple facilities. In these situations, real time collaboration and reliable real time updates are essential. They help teams stay aligned, meet due dates, and maintain accountability across departments.

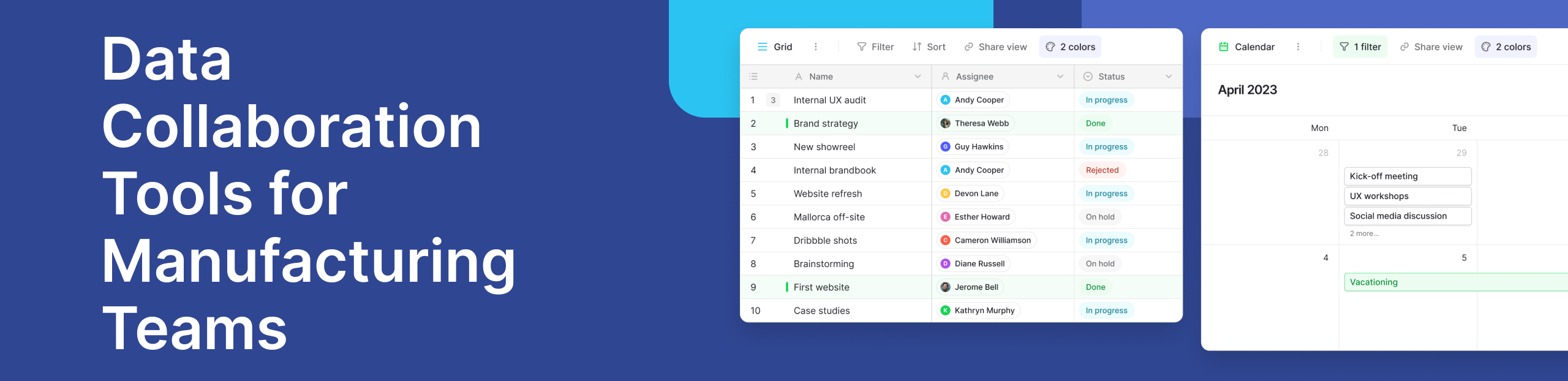

Flexible, database-driven collaboration platforms provide a practical way to support this work. Tools like Baserow allow manufacturing teams to create shared workspaces that reflect their processes, instead of forcing them into fixed templates. By structuring operational data in a user friendly way, these platforms help improve visibility without adding unnecessary complexity.

Why Data Collaboration Is Critical in Modern Manufacturing

Manufacturing has moved beyond isolated production lines. Today, operations depend on connected workflows across procurement, production, quality assurance, logistics, and finance. Each team relies on accurate and up-to-date data from the others. When information is spread across separate systems, teams spend more time matching numbers than improving processes.

Poor data collaboration often leads to slow responses, inconsistent reports, and missed improvement opportunities. For example, a quality issue recorded in one system may not reach production planners in time. This can result in rework or unplanned downtime. Effective collaboration software reduces these risks by keeping everyone aligned around a shared and continuously updated data source.

The growth of distributed manufacturing teams has increased the need for structured collaboration. Plants operating in different regions must align on standards, schedules, and performance metrics. Team communication alone is not enough when the underlying data is outdated or inconsistent. A team collaboration tool that combines communication with shared operational data creates a stronger foundation for coordination.

In many manufacturing environments, coordination also depends on video conferencing to connect teams during shift handovers, incident reviews, or production planning sessions. When live discussions are supported by shared and current operational data, teams can resolve issues faster and make decisions with greater confidence. This reduces reliance on static reports or follow-up emails.

Data driven manufacturing also requires historical visibility. Teams need to review trends, identify bottlenecks, and learn from past performance. Without proper version control and traceability, reports become harder to trust and improvements are difficult to confirm. Modern collaboration platforms address this by tracking changes over time and maintaining clear audit trails.

What Are Data Collaboration Tools in Manufacturing?

Data collaboration tools in manufacturing allow multiple team members to work together using shared datasets in a structured and controlled way. Instead of exchanging static files, teams work with live data that updates as changes are made. This helps keep planning, execution, and review activities aligned.

A common example of data collaboration is a shared production planning database. Planners update schedules, supervisors record progress, and managers review performance metrics in near real time. Everyone works from the same information, which reduces confusion and duplicate work. This approach differs from traditional project management software, which often focuses on tasks without fully connecting operational data.

Collaborative manufacturing depends on this shared data foundation. It allows teams to coordinate processes, manage dependencies, and respond faster when conditions change. By combining structured data with collaboration tools, manufacturers can support more flexible and responsive operations.

Many modern platforms also include ai powered features that support data analysis and pattern recognition. These tools help teams identify trends and insights within complex datasets, without requiring advanced technical skills. When used responsibly, AI can improve visibility while keeping sensitive operational data under control.

Key Features Manufacturing Teams Should Look For

- Real-Time Data Sharing and Visibility

At the heart of effective data collaboration is the ability to share updates instantly. Manufacturing teams need real time updates to respond to machine issues, supply delays, or quality deviations. A collaboration platform that supports real time collaboration ensures that decisions are based on current information rather than outdated reports.

- Structured Collaboration Across Teams

Manufacturing involves many roles, each with different responsibilities. Collaboration tools should allow teams to organise data in ways that reflect their workflows, whether that involves tracking tasks, managing schedules, or monitoring performance. Features such as kanban boards can help visualise work in progress and improve coordination across departments.

- Version Control and Accountability

Reliable version control is essential in manufacturing, where documentation and process changes must be carefully managed. Collaboration software should record who made changes and when, supporting traceability and compliance. This builds trust in the data and reduces the risk of errors.

- Flexible Integration and Usability

Manufacturing teams often use multiple systems, from ERP platforms to quality management tools. Seamless integrations allow collaboration platforms to fit into existing environments without disruption. At the same time, tools must remain user friendly so that all team members can participate without extensive training.

Why Must It Go Beyond Spreadsheets

For many years, spreadsheets have been the default way to manage manufacturing data. They are flexible and easy to use, but they were not designed for real time collaboration across complex operations. When multiple teams edit, share, and duplicate files, version conflicts and data inconsistencies quickly appear.

File sharing systems improve access to information, but they do not solve the core problem. Teams can still work with outdated files, miss important updates, or struggle to identify the correct data source. In manufacturing environments where accuracy and timing matter, these issues often lead to errors and delays.

Modern collaboration platforms solve these limitations by treating data as a shared asset instead of a static file. Rather than passing documents between teams, users collaborate directly within structured datasets. This approach supports clearer ownership, stronger coordination, and faster responses to operational changes.

AI and Data Collaboration in Manufacturing

Manufacturing produces large amounts of operational data, including production metrics and quality records. Turning this data into useful insight is now easier with ai powered capabilities built directly into collaboration software.

AI-assisted features help teams identify trends, flag anomalies, and reduce manual data work. For example, pattern recognition can reveal repeated quality issues or delays before they grow into larger problems. When these insights are part of a shared data environment, the right stakeholders can access them immediately.

Security and governance remain important, especially in regulated or security-sensitive industries. Recent advances in data collaboration focus on responsible AI use, ensuring that automation supports decision-making without reducing control. This balance is critical in manufacturing, where compliance and traceability play a key role.

Baserow for Manufacturing Teams

Manufacturing teams often need tools that adapt to their processes instead of forcing fixed workflows. Baserow uses a no-code, database-driven approach that allows teams to build collaboration spaces around their operational data. Rather than choosing between spreadsheets and complex enterprise systems, teams can create structures that support production planning, quality tracking, and supplier coordination.

Baserow’s product overview explains how structured data models improve visibility while remaining accessible to non-technical users. Teams can build shared databases to track production runs, log issues, or manage maintenance schedules. At the same time, they can maintain clear permissions and data ownership across teams.

Recent platform updates introduced stronger automation and AI-assisted capabilities. These improvements help teams gain insights faster and reduce manual work. For manufacturing organisations that need to scale collaboration, these features support growth without adding operational complexity. Additional details are covered in the Baserow 2.0 release notes and in industry coverage of its AI-powered data collaboration workspace for security-sensitive environments.

A Practical Manufacturing Use Case

Consider a mid-sized manufacturer operating several production lines. Production planners manage schedules, supervisors track daily output, and quality teams record inspection results. In many cases, this information is spread across spreadsheets, emails, and separate tools.

With a shared data collaboration workspace, the organisation can centralise this information in one system. Planners update schedules directly in the database, supervisors record progress as it occurs, and quality teams log issues that become instantly visible to operations. Managers gain clear visibility into bottlenecks and performance trends, which supports faster and more data driven decisions.

This approach improves accountability and reduces the time spent reconciling information. It also scales as operations grow, allowing teams to add new views or workflows without disrupting existing processes.

Learning from the Baserow Community

Real-world usage often shows how flexible tools perform in practice. Within the Baserow community, manufacturing and operations teams regularly share how they adapt the platform for production tracking, inventory visibility, and cross-functional coordination.

A common theme across these discussions is the value of starting simple. Teams appreciate the ability to evolve their data structures over time instead of committing to a rigid system from the start. This gradual approach aligns well with continuous improvement practices used in manufacturing.

Check out Baserow’s webinar on how to Boost Manufacturing Performance with Real Time Data Collaboration Apps

Data Governance & Shared Manufacturing

Collaborative manufacturing depends on strong data governance. Shared datasets must remain accurate, consistent, and secure. In manufacturing environments, shared data usually includes operational data, quality records, planning information, and performance metrics.

Data governance is often described using the 5 C’s: clarity, consistency, control, compliance, and collaboration. Data collaboration tools that support permissions, audit trails, and structured access help teams follow these principles without slowing down daily work.

Research from organisations such as McKinsey and standards bodies like ISO highlights the importance of strong data governance in improving manufacturing performance and resilience. Aligning collaboration practices with these principles strengthens both operational efficiency and compliance.

Frequently Asked Questions

- What is an example of data collaboration?

A shared production planning database where multiple teams update schedules, track progress, and review performance metrics in real time is a common example in manufacturing.

- What is collaborative manufacturing?

Collaborative manufacturing refers to coordinated operations where teams, systems, and partners work together using shared data to improve efficiency, quality, and responsiveness.

- What are the 4 types of shared data?

In manufacturing, shared data often includes operational, quality, planning, and performance data, each supporting different aspects of decision-making.

- What are the 5 C’s of data governance?

The 5 C’s typically include clarity, consistency, control, compliance, and collaboration, forming a framework for managing shared data responsibly.

Choosing the Right Tool

Selecting the right collaboration tool depends on flexibility, governance, and ease of use. Manufacturing teams benefit most from platforms that support structured data, integrate with existing systems, and adapt as processes evolve. Tools that combine these capabilities help organisations move beyond fragmented workflows toward unified visibility.

If you’re exploring ways to improve manufacturing data collaboration, Baserow offers a practical starting point. Its adaptable approach allows teams to build what they need today while remaining ready for tomorrow.

To explore how structured data collaboration can support your manufacturing operations, you can get started with Baserow.

Baserow 2.1 is a maintenance-focused release that improves performance, security, and reliability. It introduces Expert formula mode, Nuxt 3 and Django upgrades, bug fixes, PostgreSQL 14+ support for self-hosters, and a new Ukrainian translation.

Discover how Airtable and Baserow compare in features, flexibility, speed, and scalability. Compare pricing plans and hidden costs to make an informed decision!

Explore the best open-source software alternatives to proprietary products. Discover OSS tools, licenses, and use cases with our updated directory.